© KLEIBERIT

Adhesive solutions for bookbinding

Do you produce books, magazines or brochures?

We offer a product range that fulfills the specific requirements of the bookbinding industry. Our reactive adhesive systems meet the highest standards for quality products in terms of processing properties, handling and quality. They are suitable for almost all standard application methods and are successfully used with the equipment of renowned manufacturers.

Our bookbinding adhesives comply with the latest safety, health and environmental protection standards.

© KLEIBERIT

© KLEIBERIT

Energy-saving – low-emission – efficient

We offer classic bookbinding adhesives and a new generation of polyurethane-based hotmelts. Our E-Melt PUR hotmelt series can be processed at very low temperatures between 80°C and 100°C, for energy-saving manufacturing. The bonding properties of the E-Melt series products are equivalent to those of conventional PUR bookbinding adhesives.

Our low-emission bookbinding hotmelt KLEIBERIT 712.3 ME contains less than 0.1% monomeric isocyanate, meaning it no longer needs to be labelled with hazard statements G + H. The bonding quality is nevertheless identical to conventional PUR bookbinding adhesives.

Take a look at our product table and contact our experts for advice.

EVA hotmelts

KLEIBERIT 734.0.00 Hotmelt

- gluing book spines with a nozzle/roller

KLEIBERIT 734.9.00 Hotmelt

- gluing book spines

- gluing pages

KLEIBERIT 773.1.00 Hotmelt

- gluing book spines

- gluing pages

Reactive PUR hotmelts

KLEIBERIT 712.3.00 Reactive ME hotmelt

- free of labeling

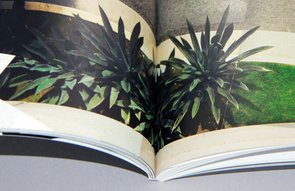

- high-quality catalogues, brochures, books

KLEIBERIT 712.6.00 Reactive hotmelt

- low-emission, low temperature hotmelt

- very short open time

- very high initial strength

- high-quality catalogues, brochures, books

KLEIBERIT 712.7.00 Reactive hotmelt

- low-emission, low temperature hotmelt

- high-quality catalogues, brochures, books